Trusted by Scientists Around the World

.svg.png)

Enhance Your Automation Arsenal

Practice Sustainability

Use a fraction of the pipette tips required by traditional automation, save the planet, and retain your budget.

Conserve Reagents

Dispense reagents with <1 μL dead volume and run more samples for the same reagent cost.

Generate Trustworthy Results

Dispense 8 nL to 30 μL with 0.1 nL resolution into any SBS format destination labware with a high degree of precision.

Trust Your Process

Dispense with insight into the actual volume dispensed every time with integrated volume verification and re-dispense missed droplets.

Forget About Training

Software for dispensing a constant volume, dilution, normalization, and pooling should not be complicated.

Deliver Value to Your Lab

Dispense up to 384 source liquids per run at a speed and precision that will continue to surprise you and your colleagues every day.

Fast. Precise. Traceable.

The I.DOT is an intuitive liquid handling system designed for researchers of all experience levels. This breakthrough technology precisely dispenses volumes as low as 8 nL with unrivaled accuracy and speed, while dramatically reducing your laboratory's plastic waste and reagent consumption.

From dispensing sensitive enzymes and beads for NGS or qPCR to precisely delivering cells, compounds, and buffers for assay development and high-throughput screening, the I.DOT delivers exceptional precision and remarkable ease of use. The result? More efficient workflows and consistently reproducible sample preparation that transforms your research capabilities.

Enabling Miniaturization is Our Passion

Although reaction miniaturization is ubiquitous in large pharmaceutical environments, it can be challenging to understand the risks and considerations associated with generating high-quality data in the context of miniaturizing assays.

The DISPENDIX team has worked through miniaturization of even the most complex NGS workflows and can help you to scale volumes as low as 1/10th the manufacturer's recommended SOP without compromising data quality.

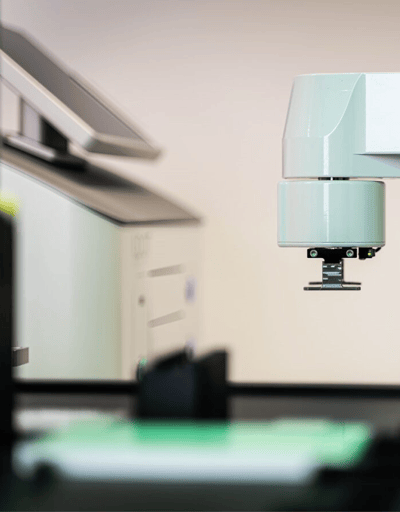

Designed for Automation

The I.DOT Liquid Handler has been designed so that I.DOT Source Plates and destination SBS format labware can be reproducibly loaded into the device for reliable integration into any automated work cell.

With a SiLA2 compliant API and comprehensive integration manual, third party integrators can seamlessly and efficiently incorporate the I.DOT into any automated solution to maximize efficiency, reproducibility, and process safety.

Introducing the I.DOT LT Non-Contact Dispenser

The I.DOT LT Liquid Handler delivers exceptional precision with dispensing capabilities from 17.3 nL to 30 µL at an impressive resolution of 0.1 nL. This compact system eliminates human error while supporting any SBS format target plate including 1536-well plates, making it the ideal solution for laboratories seeking to maximize efficiency with precious reagents.

With its tip-reduced workflow and minimal implementation time, the I.DOT LT brings advanced liquid handling within reach for all labs. The system enables true miniaturization of assays to process more samples at the same cost, while its 12 disposable source wells (each holding up to 490 µL) optimize reagent usage and minimize waste—delivering immediate value through improved efficiency and resource optimization.

Choose the Best Fit for Your Application

-

I.DOT LT

-

I.DOT S

-

I.DOT L

-

I.DOT HT

I.DOT L Passive Cooling Heating Module

The Passive Cooling Heating Module is designed for non-contact dispensing of whether temperature-sensitive reagents such as enzymes, antibodies, PCR master mixes, and Matrigel or sensitive reagent solution which needs to be heated up to improve solubility or prevent crystallization. This module ensures stable and uniform temperatures making it the ideal solution for your lab’s needs.

It can be placed directly in the freezer, fridge or water bath, or incubator for easy pre-tempering and is designed for seamless integration with your existing I.DOT L setup.

Say goodbye to the challenges of temperature-depending dispensing and experience the precision and efficiency of the Passive Temperature Module!

Our Most Common Questions

How do I know which steps of my process the I.DOT can automate?

Is the I.DOT automation friendly?

Yes! Our customers integrate the I.DOT in varying degrees of complexity from simple integrations with an arm and a liquid handler to large robotic workcells capable of processing thousands of samples per day.

Can the I.DOT Dispense Glycerol, DMSO, and Aqueous Solutions?

The I.DOT can dispense liquids from 0.55 mPa*s (methanol) to 23.32 mPa*s (65% glycerol).

How do I know that the I.DOT actually dispensed my liquid?

The I.DOT comes equipped with integrated droplet detection that counts the number of droplets dispensed in any given operation. With these data, the I.DOT software will report to you the theoretical volume dispensed by taking the product of the average droplet size and number of droplets counted.

Request a Quote

The Complete Guide to Automated Pipetting

Explore the evolution and impact of automated pipetting technology. By embracing automated pipetting, labs can achieve faster, more reliable, and safer workflows.