Successful assessment of small molecule compound storage in I.DOT HT Source Plates at 4°C and -20°C using cellular assays

This white paper highlights the compound storage capabilities of I.DOT HT source plates in combination with the Roylan Developments StoragePod system. The results not only affirm the suitability of I.DOT HT.60 source plates for storing small molecule compounds but also demonstrate that the I.DOT non-contact, low-volume liquid handler determined AC50 values of 21 small molecule compounds reproducibly. Furthermore, these data suggest that the I.DOT performs equally well compared to the Echo Acoustic Liquid Handler in terms of both source plate storage and dispensing performance, while offering multiple substantial advantages over the acoustic dispensing technology.

The Immediate Drop on Demand Technology (I.DOT; Fig. 1) is ideally suited for low-volume, high throughput applications. It allows dispensing volumes as low as 2.55 nL at a 0.1 nL resolution through eight independent dispensing channels, offering flexibility in droplet size at a speed of 100 droplets per second. The droplets are dispensed from a pore at the bottom of the 96-well or 384-well source plate and each droplet is detected and counted by an optical sensor before entering the target plate. The technology dispenses target volumes at a precision of <8% CV while providing in-process quality control.

The Roylan Developments StoragePod system (Fig. 1) allows for storing lidded I.DOT source plates in a hermetically sealed storage environment. The user simply places the SBS format lab ware in the StoragePod and closes the system. The StoragePod utilizes a flow of nitrogen to create a dry, low oxygen and moisture content storage environment. This controlled atmosphere is maintained until the user decides to access the StoragePod for retrieving stored compounds. Various designs of StoragePods are available, and their modular nature allows for the use of multiple pods, offering flexibility and expansion to meet evolving storage needs.

Figure 1. DISPENDIX I.DOT HT non-contact, low-volume liquid handler (left), Roylan

Developments Storage Pod (middle), HT.60 Source Plate for I.DOT HT (right)

Materials and Methods

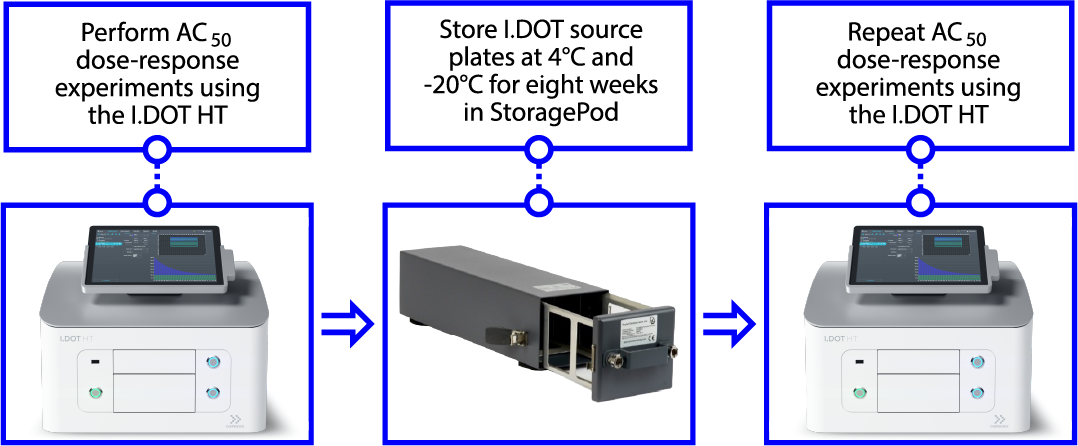

To assess the storage capabilities of I.DOT source plates, dose-response curves of 21 small molecule compounds (90% DMSO, highest compound concentration 10 µM) were transferred from a stock plate to 384-well I.DOT HT source plates (HT.60 plates). Subsequently, 250 nL of each compound dilution were dispensed from the source plate into 384-well intermediate plates. These intermediate plates were used to conduct a fluorescence cell viability assay with HEK293 cells. Following the completion of the experiment at day zero using two source and intermediate plates, a set of two lidded I.DOT source plates were placed in a StoragePod and stored for eight weeks at 4°C and -20°C, respectively. After storage period, the HT.60 source plates were utilized to repeat the cell viability assay. In parallel, the same experiment (Fig. 2) was carried out using an Echo liquid handler and the corresponding source labware.

Figure 2. Experimental Workflow

Results

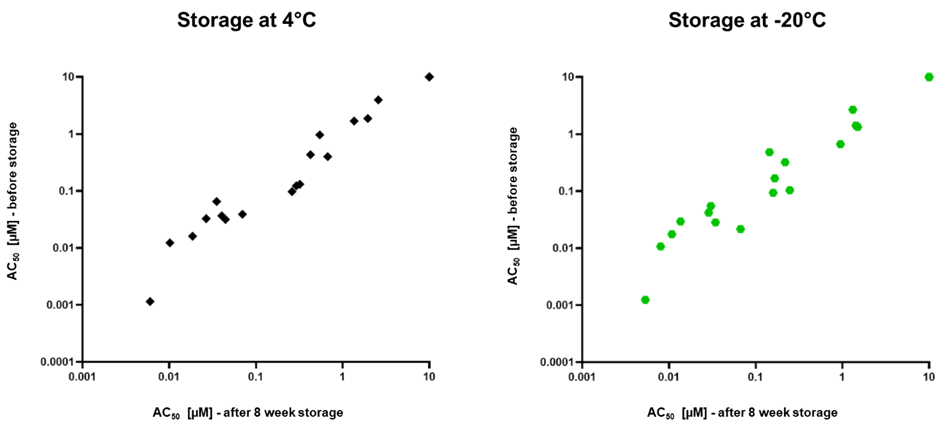

After completion of the experiments, AC50 values (half-maximum response concentrations) were determined for the 21 compounds both before and after the eight-week storage period. Using a Pearson correlation analysis, the measured AC50 values were compared against the recorded AC50 values.

With a strong correlation before (r = 0.9850 , P < 0.0001) as well as after the eight weeks storage period (4°C storage: r = 0.9730, P < 0.0001 ; -20°C storage: r = 0.9730, P < 0.0001), these data showcase the efficacy of I.DOT HT.60 source plates for compound storage as well as the ability of the I.DOT to consistently reproduce the recorded AC50 values.

When comparing the AC50 values before and after the eight-week storage period, these data suggests that there is no significant impact of storage at 4°C or 20°C (Fig. 3).

Figure 3. Correlation of AC50 values before and after eight week storage at 4°C and -20°C. Pearson correlation for 4°C storage: r = 0.9968 , P < 0.0001. Pearson correlation for -20°C storage: r = 0.9972 , P < 0.0001.

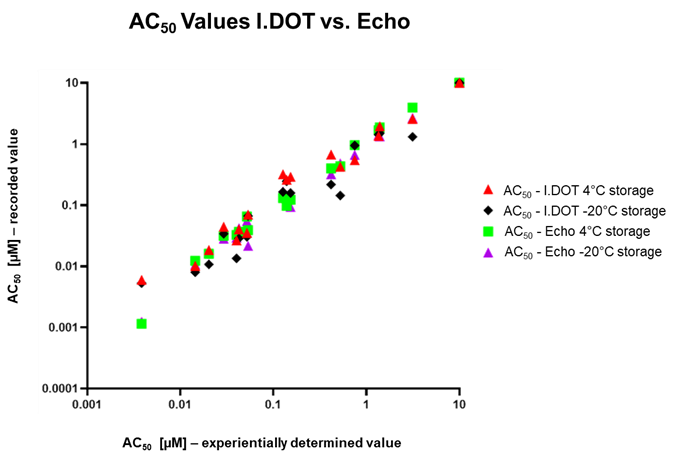

Further, the AC50 values obtained with the I.DOT non-contact, low-volume liquid handler showed robust correlation with the AC50 values obtained using the Echo acoustic liquid handler for both 4°C and -20°C storage conditions (r = 0.9987, P < 0.0001, and r = 0.9997, P < 0.0001, respectively).

Figure 4. AC50 values determined using the I.DOT vs. Echo determined values. Pearson correlation I.DOT vs. Echo, 4°C storage: r = 0.9987 , P < 0.0001. Pearson correlation I.DOT vs. Echo, -20°C storage: r = 0.9997 , P < 0.0001

The data presented in this white paper underscores the potential of I.DOT HT.60 source plates for compound storage and highlights the ability of the I.DOT system to reliably dispense small molecule compounds for dose-response experiments. Furthermore, the comparison of AC50 values between the I.DOT and the Echo liquid handler showed a robust correlation at both 4°C and -20°C storage conditions. This emphasizes the reliability of the StoragePod system for I.DOT source plate storage.

Click here to view more information about Dose Response Curves.

Click here to download the I.DOT brochure

Click here to download the full white paper.