The Role of Miniaturized Reactions in Modern Laboratories

Miniaturized reactions enhance research by reducing reagent waste, increasing throughput, and improving accuracy, while automated solutions minimize...

This blog post covers essential considerations related to choosing a solution for automated pipetting (liquid handling) in your laboratory.

In today's rapidly advancing scientific landscape, laboratories are under constant pressure to increase efficiency, improve accuracy, and streamline workflows. Manual pipetting, once the standard method of liquid transfer, is gradually being replaced by automated pipetting systems that offer significant advantages in terms of throughput, precision, and cost savings.

This blog post will cover essential considerations related to automated pipetting, equipping you with the knowledge necessary to navigate the complexities of this technology. We will introduce the various types of automated pipetting systems, explore different displacement technologies, discuss cost considerations, and highlight the key components and benefits of automated pipettors.

We will note the crucial factors you need to consider when purchasing an automated pipettor, ensuring that your chosen solution aligns perfectly with your laboratory's unique requirements. From throughput and reproducibility to sample volumes and safety considerations, we'll guide you through the decision-making process.

Whether you are just starting to explore automation possibilities or looking to upgrade your existing liquid handling systems, our goal is to empower you with the knowledge and insights necessary to optimize your laboratory workflows effectively.

Automated pipetting is a revolutionary technology that has transformed liquid handling processes in laboratories worldwide. This method involves the use of advanced robotic systems to transfer precise volumes of liquid from a source location to a destination located within the same or a different SBS format labware. By automating this essential task, laboratories can reap a multitude of benefits that greatly enhance their efficiency and productivity.

One of the primary advantages of automated pipetting is the substantial increase in throughput. Unlike manual pipetting, which is time-consuming and limited by human dexterity and speed, automated systems can perform pipetting tasks at a much faster rate. These systems can handle a large number of samples simultaneously, enabling laboratories to process more samples in a shorter amount of time. This enhanced throughput is particularly beneficial for high-throughput screening, sample preparation, and other applications that require rapid liquid transfers.

Accuracy is paramount in scientific research and analysis. Automated pipetting systems excel in delivering precise and consistent volumes of liquid, significantly reducing human error and variability. These systems employ advanced technologies such as air displacement, positive displacement, or acoustic droplet ejection, which ensure accurate and reproducible liquid transfers, even for small volumes. By minimizing errors associated with manual pipetting, laboratories can achieve reliable and reproducible results, leading to more robust data and improved experimental outcomes.

Automated pipetting streamlines laboratory workflows by minimizing repetitive manual pipetting tasks. By automating liquid transfers, scientists and technicians can focus on other critical aspects of their research, such as data analysis and experimental design. This optimization of human resources leads to increased efficiency and productivity within the laboratory. Additionally, automated pipetting systems often integrate with other laboratory instruments and software, enabling seamless workflow integration and data traceability.

The time saved by adopting automated pipetting systems is invaluable in a laboratory setting. By reducing the time spent on pipetting tasks, researchers can allocate more time to higher-value activities, accelerating the pace of scientific discovery. Moreover, automated pipetting systems eliminate the need for repetitive pipetting by hand, reducing the risk of repetitive strain injuries (RSIs) and promoting a healthier work environment. Additionally, the cost savings associated with automated pipetting stem from increased efficiency and reduced waste, as precise liquid transfers minimize sample and reagent consumption.

Automated pipetting offers laboratories a multitude of benefits that enhance throughput, accuracy, and overall workflow efficiency. By understanding and embracing this technology, laboratories can revolutionize their liquid handling processes, leading to improved experimental outcomes, increased productivity, and cost savings.

When it comes to adopting automated pipetting systems, laboratories have three main categories to consider: manual, semi-automated, and fully automated systems. Each category offers distinct levels of automation, and the choice depends on the specific requirements and workflows of the lab. Let's delve into the details of each category to help you make an informed decision.

Manual pipetting involves performing the entire pipetting process manually, using handheld pipettes and performing the liquid transfers by hand. While this method has been widely used for decades and is suitable for many routine laboratory tasks, it is limited by human dexterity, precision, and speed. Manual pipetting is time-consuming, and the risk of human error and variability is higher compared to automated systems. However, it remains a cost-effective option for laboratories with lower throughput requirements or limited budgets.

Semi-automated pipetting systems offer a middle ground between manual and fully automated systems (Fig. 1). These systems combine manual pipetting steps with automated features, such as electronic pipettes or pipetting robots. With semi-automated systems, researchers still perform certain steps manually, such as loading samples or reagents into the system, but the actual liquid transfers are automated. This level of automation improves accuracy and consistency while reducing the risk of human error. Semi-automated systems are versatile and can be a suitable choice for laboratories with moderate to high throughput needs, as they provide a balance between cost, flexibility, and automation.

Figure 1. With bench-top semi-automated systems, like the I.DOT Non-Contact Dispenser, researchers still perform certain steps manually, such as loading samples or reagents into the system, but the actual liquid transfers are automated.

Fully automated pipetting systems provide complete walk-away automation, eliminating the need for manual intervention during the pipetting process. These systems feature robotic arms, integrated software, and automated liquid handling modules that can perform complex pipetting tasks with high precision and throughput. Fully automated systems are particularly beneficial for laboratories with high sample volumes, complex workflows, or stringent accuracy requirements. They can handle large batches of samples, perform repetitive pipetting tasks with consistent precision, and seamlessly integrate with other laboratory instruments and software. Although fully automated systems offer the highest level of automation and efficiency, they tend to be more expensive and may require specialized training or expertise for operation and maintenance.

When choosing between manual, semi-automated, and fully automated pipetting systems, several factors come into play. These include the laboratory's throughput requirements, the complexity of the workflows, budget constraints, and the need for flexibility and integration with other instruments or software. Manual pipetting is suitable for lower throughput or budget-conscious labs, while semi-automated systems strike a balance between cost and automation. Fully automated systems excel in high-throughput environments with complex workflows and require a higher initial investment but offer significant time and labor savings in the long run.

Bench-top solutions, whether semi-automated or fully automated, are often a more affordable and versatile option for a wide range of applications (Fig. 1). They occupy less space, require fewer infrastructure modifications, and offer scalability to accommodate future expansion or changing needs.

The choice between manual, semi-automated, and fully automated pipetting systems depends on your laboratory's specific requirements, throughput demands, and budget considerations. Evaluating your workflow needs and considering the level of automation required will help you select the most appropriate system to enhance productivity, accuracy, and efficiency in your lab.

Automated liquid transfer systems employ various displacement technologies based on volume ranges and liquid types. Air displacement pipetting relies on an air cushion to move the liquid, while positive displacement pipetting uses direct contact between the liquid and a piston for precise and repeatable delivery. Non-contact technology, on the other hand, employs pressure pulses or sound waves to transfer small droplets of liquid. Each technology has its strengths and limitations, and the choice depends on factors such as the volume range and liquid characteristics required for your lab's workflows.

Air displacement pipetting is a commonly used technology that relies on creating an air cushion to transfer liquids. In this method, a pipette aspirates the liquid by creating a vacuum within the pipette tip. When dispensing, the air pressure is released, allowing the liquid to be expelled. Air displacement pipetting is suitable for a wide range of volumes, from microliters to milliliters. It offers versatility and is compatible with various liquid types. However, it may not be suitable for volatile or viscous liquids, as they can disrupt the air cushion and affect accuracy.

Positive displacement pipetting involves direct contact between the liquid and a disposable piston or tip. As the piston moves, it physically displaces the liquid, ensuring precise and repeatable delivery. This technology is particularly useful for transferring viscous or volatile liquids, as it eliminates the air cushion and minimizes the risk of contamination. Positive displacement pipetting is often preferred for low-volume applications, such as handling microliter volumes. However, it may require specialized tips and is not suitable for transferring large volumes due to the limitations of the disposable piston or tip.

Non-contact dispensing technology is a relatively newer method used for transferring small droplets of liquid (Fig. 2). It utilizes pressure pulses or sound waves to generate pressure waves that eject tiny droplets from a source onto a target. Non-contact liquid handling systems can precisely control the volume of each droplet by adjusting the frequency and intensity of the pressure or sound waves.

Figure 2. I.DOT Source Plates allow researchers to dispense anywhere from 3 nL to 50 nL at 0.1 nL resolution with <1 μL dead volume, without the need for costly pipette tips.

This technology is particularly advantageous for high-throughput applications where precise nanoliter or picoliter volumes are required. Non-contact technology offers contactless dispensing, reducing the risk of cross-contamination and sample carryover. Although non-contact dispensing can reduce pipette tip consumption overall, it is not relevant for steps that require aspiration of many source liquids such as plate replications or bead-based clean-ups.

Non-contact technology offers contactless dispensing, reducing the risk of cross-contamination and sample carryover.

When selecting a displacement technology for your automated liquid transfer system, it is essential to consider factors such as the volume range, liquid characteristics (viscosity, volatility), application requirements, and the level of precision and accuracy needed. Each technology has its advantages and limitations, and choosing the right one will ensure optimal performance and reliability in your laboratory workflows.

The cost of automated pipetting systems depends on the functionality and complexity of the system, and it's important to consider the upfront and service costs while also assessing the long-term cost savings and return on investment.

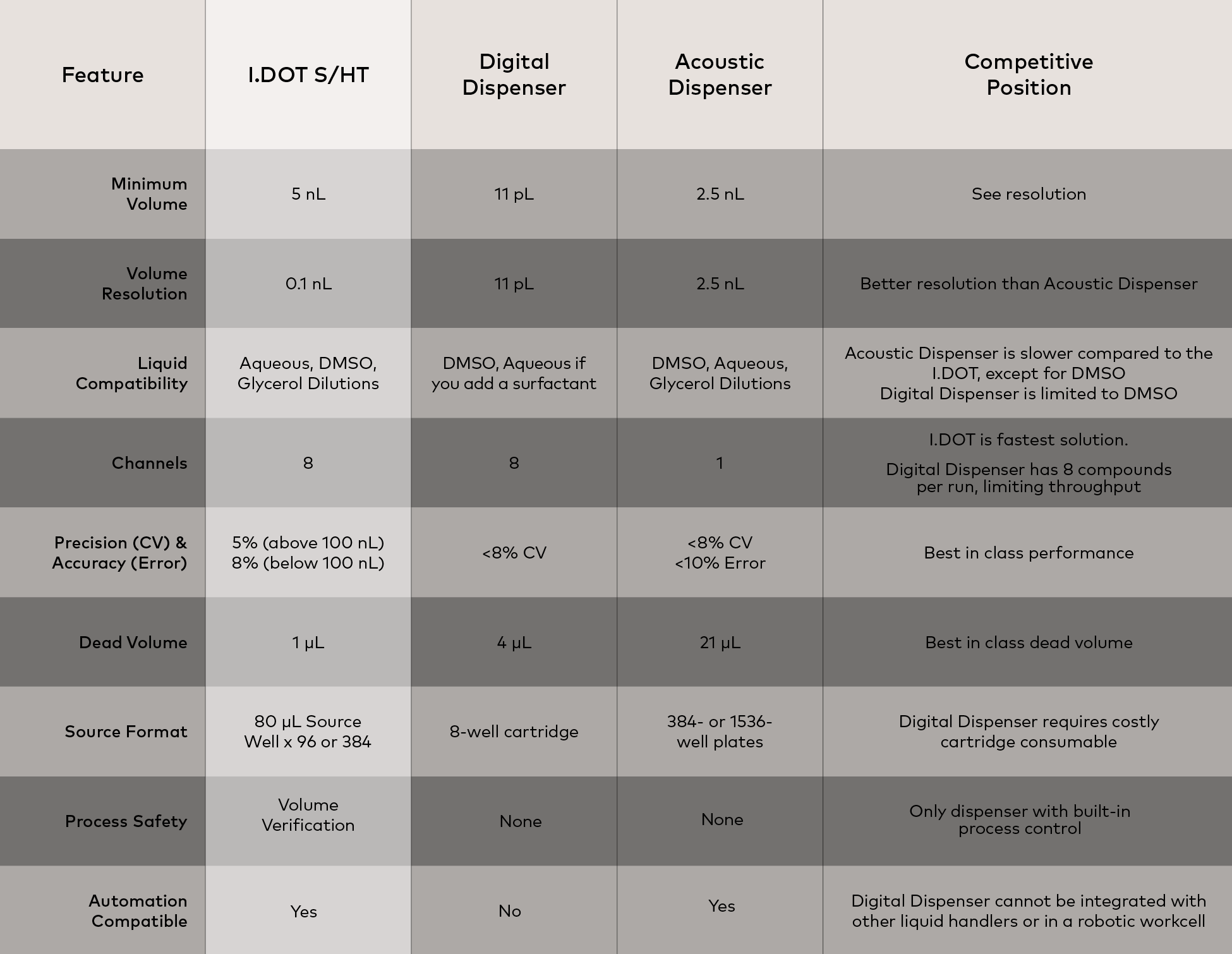

The cost of automated pipetting systems can vary significantly, typically ranging from tens of thousands to hundreds of thousands of dollars (Table 1). The price depends on several factors, including the functionality, features, throughput capacity, precision, and complexity of the system. Off-the-shelf pipettors that offer standard capabilities and configurations tend to be more affordable, while customized workflow solutions designed to meet specific laboratory requirements may have a higher price tag.

Table 1. Summary of the I.DOT Liquid Handler's benefits over other popular automated pipetting systems on the market.

When considering the cost of an automated pipetting system, it's essential to account for the upfront investment. This includes the purchase price of the system itself, which can vary based on the manufacturer, model, and specifications. Additionally, there may be costs associated with accessories, such as tips, consumables, and any required software licenses. It's crucial to carefully evaluate the features and capabilities offered by different systems to ensure they align with your laboratory's needs and budget.

When considering the costs of automated pipetting systems, it is crucial to assess both the upfront investment and the long-term cost savings and ROI. Evaluating the functionality, features, service options, and potential benefits of different systems will help you make an informed decision that aligns with your laboratory's requirements and budgetary considerations.

Automated pipettors consist of several key components, including the pipetting head (multi-channel or single-channel), control interface (linked PC or inbuilt touchscreen computer), liquid handling core (fixed or interchangeable), deck (for securing consumables), and pipette tips (permanent or disposable). These components work together to enable automated pipetting and dispensing tasks.

The pipetting head is a crucial component of automated pipettors and comes in two main configurations: multi-channel and single-channel. Multi-channel pipetting heads have multiple channels (usually 8 or 12) that allow simultaneous pipetting of multiple samples. Single-channel pipetting heads, on the other hand, handle one sample at a time. The choice between multi-channel and single-channel heads depends on the specific application requirements and the number of samples that need to be processed.

Automated pipettors feature a control interface that enables users to operate the system. The control interface can be either a linked personal computer (PC) or an inbuilt touchscreen computer. Linked PC interfaces provide advanced software capabilities and data management options, allowing users to control the pipettor through dedicated software. Inbuilt touchscreen interfaces offer a user-friendly experience and may have built-in protocols or applications for simplified operation.

The liquid handling core is the central component responsible for aspirating and dispensing liquid samples. It consists of mechanisms that control the movement of liquids, such as pumps, valves, and syringes. The liquid handling core can be either fixed or interchangeable, depending on the system's design. Fixed liquid handling cores are integrated into the pipettor and offer a specific range of volume capacities. Interchangeable liquid handling cores provide flexibility by allowing users to switch between different volume ranges or specialized liquid handling modules based on their application needs.

The deck of an automated pipettor serves as a platform for securing consumables and samples during pipetting operations. It typically features various positions or slots where plates, tubes, or other labware can be placed. The deck may also include additional features such as heating or cooling elements, shaking modules, or barcode readers for automated sample tracking and identification.

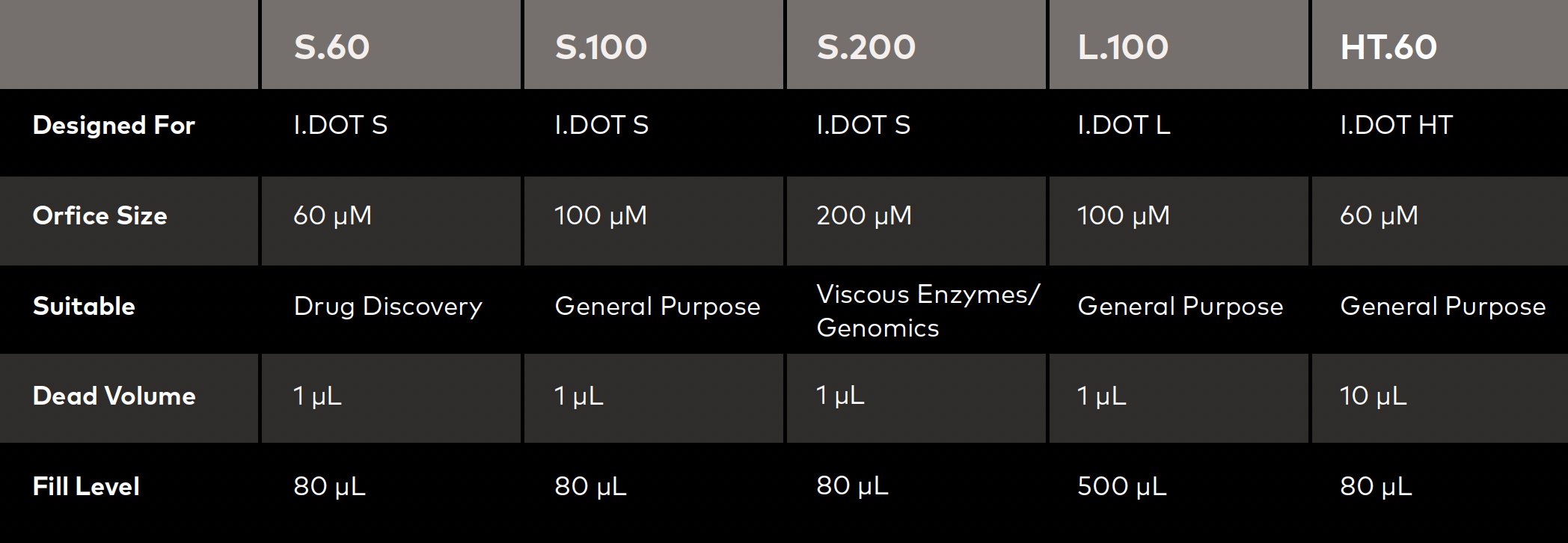

Pipette tips are essential accessories used in automated pipetting systems for aspirating and dispensing liquid samples. They come in different sizes and designs to accommodate various sample volumes and specific applications. Pipette tips can be permanent (washable and reusable) or disposable (single-use) depending on the system and the desired level of contamination control. Disposable tips are commonly used to prevent cross-contamination between samples and simplify the workflow by eliminating the need for washing and decontamination steps. Non-contact liquid handlers, like the I.DOT Non-Contact Dispenser, don't require pipette tips at all, yet maintain contamination-free experiments. The core of the technology is in the source plates, tailor-made for specific applications (Table 2).

Table 2. Overview of I.DOT Source Plates, the core of DISPENDIX's non-contact technology.

These key components of automated pipettors work together to enable precise and efficient liquid handling tasks. The pipetting head determines the sample throughput and handling capacity, while the control interface allows users to control the system and manage protocols. The liquid handling core is responsible for accurate aspiration and dispensing, and the deck provides a platform for holding consumables. Pipette tips, whether permanent or disposable, facilitate the transfer of liquids.

Understanding the functionality and features of these components will help you choose an automated pipettor that best suits your specific laboratory requirements and workflows.

When purchasing an automated pipettor, it's crucial to consider factors such as the application requirements (single or multiple applications), the level of user expertise needed, throughput requirements, modularity options (fixed or interchangeable components), and the level of support provided by the vendor. Additionally, ensuring a steady supply of consumables, such as disposable tips, is important for uninterrupted operation.

One of the key considerations when purchasing an automated pipettor is understanding your specific application requirements. Determine whether you need the system for a single application or multiple applications. Some automated pipettors are designed for specific applications, such as genomics, drug discovery, or clinical diagnostics, while others offer versatility to accommodate a wide range of applications. Choosing a system that aligns with your application needs ensures optimal performance and compatibility with your laboratory workflows.

Consider the level of user expertise required to operate the automated pipettor. Some systems are designed with user-friendly interfaces and intuitive software, making them suitable for users with varying levels of experience. On the other hand, more advanced systems may require specialized training or technical expertise to operate effectively. Assess the skill level of your laboratory personnel and select a system that matches their proficiency to ensure smooth adoption and efficient operation.

Evaluate your laboratory's throughput requirements when choosing an automated pipettor. Consider the number of samples or plates that need to be processed within a given time frame. Automated pipettors vary in their throughput capabilities, ranging from low to high throughput systems. High throughput systems often feature multi-channel pipetting heads and advanced liquid handling capabilities, enabling rapid processing of large sample volumes. Aligning the system's throughput with your laboratory's needs ensures efficient and timely sample processing.

Consider whether you require a fixed or interchangeable liquid handling core in your automated pipettor. Some systems offer modularity, allowing you to interchange different liquid handling components based on your specific application requirements. Interchangeable heads or modules enable flexibility in accommodating different sample volumes, formats, and assay types. This modularity provides versatility and adaptability to changing experimental needs, making the system more versatile and cost-effective in the long run.

Assess the level of support provided by the vendor when purchasing an automated pipettor. Consider factors such as technical support, training, and service agreements. It is essential to choose a reputable vendor with a strong support network to ensure timely assistance in case of technical issues, software updates, or maintenance needs. Vendor support plays a crucial role in maximizing the uptime and performance of your automated pipettor, so consider this aspect carefully during the purchasing process.

Ensure a steady supply of consumables, such as pipette tips, for uninterrupted operation of your automated pipettor. Disposable tips are commonly used with automated systems, and their availability is crucial to avoid workflow disruptions. Check with the vendor or supplier about the availability and cost of compatible consumables, and assess whether they can reliably meet your ongoing needs. Consider factors such as pricing, availability, and compatibility to ensure a smooth and continuous workflow.

By considering these factors, you can make an informed decision when purchasing an automated pipettor that best suits your laboratory's needs, enhances productivity, and ensures seamless integration into your existing workflows.

Choosing the right automated solution for your laboratory requires a thorough understanding of your workflow requirements, consideration of displacement technologies, cost factors, key components of automated pipettors, and the overall benefits of automation.

The I.DOT Liquid Handler automates your workflows with unrivaled precision (down to 3 nanoliters!), boosting efficiency and saving you valuable time and money. Anyone can use it, regardless of previous automation experience, thanks to its intuitive, walkup-friendly design.

Download a brochure today to see how the I.DOT Non-Contact Dispenser can transform your research. Allow our science-minded reps assess your lab's specific needs to help you make an informed decision and optimize your laboratory's workflows.

Miniaturized reactions enhance research by reducing reagent waste, increasing throughput, and improving accuracy, while automated solutions minimize...

Liquid handler automation boosts lab efficiency by enhancing accuracy, throughput, reproducibility, and reducing contamination risk, while saving...

Point of Care Testing (POCT) are ‘simple medical assays that can be performed at the bedside of a patient, with the I.DOT.