Precision & Accuracy in Liquid Handling

Precision and accuracy in liquid handling are necessary for reproducible, reliable results. Especially when pipetting small volumes, the pipetting technique can have tremendous effects on the experimental result.

Evaluation and Optimization of Liquid Handling Performance

A key process in lab automation is dispensing liquid aliquots, for example by use of automated liquid handlers. Evaluating liquid handling performance is important for lab technicians and is based off precision and accuracy.

Differentiation between Precision & Accuracy

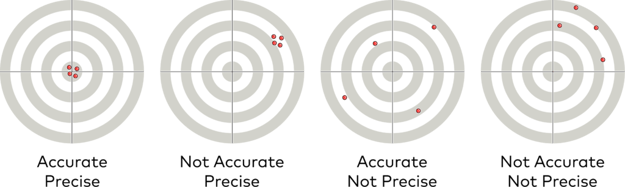

When dispensing a run of liquid aliquots with a liquid handler, the volumes will always deviate slightly from the target volume. Deviations occurs in terms of precision and accuracy.

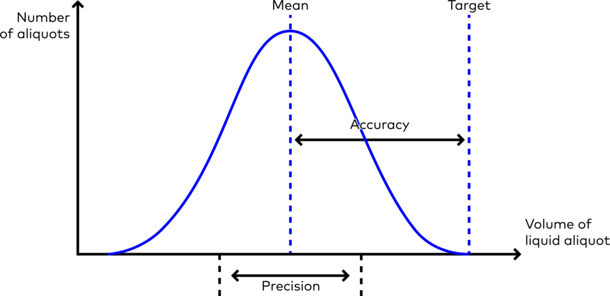

Figure 1: Graph depicts the volume distribution of a run of liquid aliquots

Precision is measured as the degree of variation between individual measured volumes within one dispensing run. Dispensed liquid aliquots are measured for volumetric reproducibility. The Coefficient of Variation (CV) is defined as the ratio of standard deviation to the mean value of a run. A precision measurement is a measure of how close aliquot volumes are to one another or how random errors occur.

Accuracy refers to deviations from the dispensing volume targeted by the form. An accurate measure of accuracy is +3 nl or +3% if a user wants to dispense a reagent with a target volume of 100 nl but receives 103 nl. An aliquot's accuracy is how close it is to the target volume based on its mean based on its aliquots.

Precision and Accuracy in Intra-run, Inter-run and Tip-to-tip Dimensions

Liquid handler manufacturers and operators must conduct an even more systematic and differentiated assessment of liquid handling performance. In order to identify error sources quickly and effectively, this is necessary. Liquid handling on microplates, for example, can be broken down into the following basic steps:

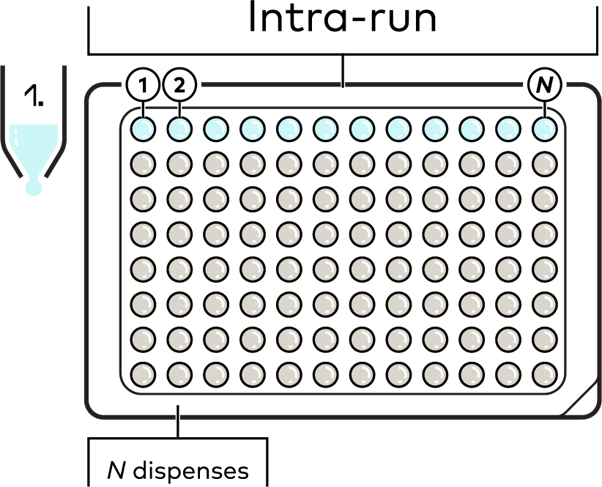

(1) Intra-run Measurements

They primarily provide information about the fundamental precision and accuracy of a single dispensing channel in a liquid handler dispensing aliquots continuously.

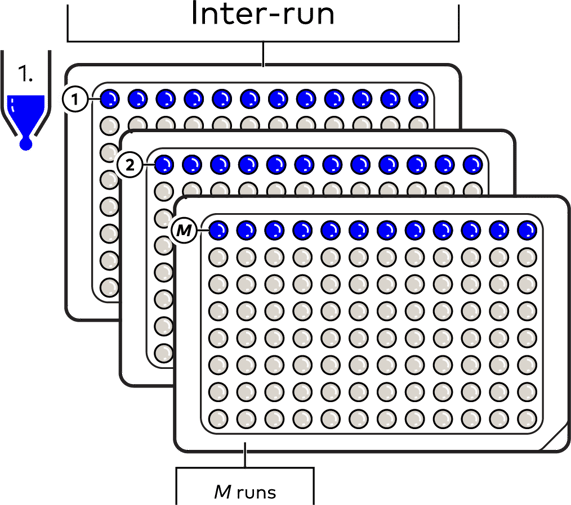

(2) Inter-run Measurements:

Identify errors caused by pause time effects and evaluate a system's stability or reproducibility. The delay time between two runs can be adjusted based on the anticipated pause times of the respective application. This ranges from a few seconds to several days.

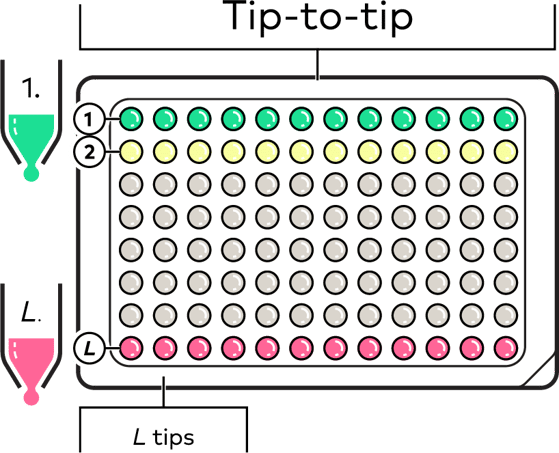

(3) Tip-to-tip Measurements

Examines dispensing channel variances (such as cartridges, nozzles, tubing, pressures, among others).

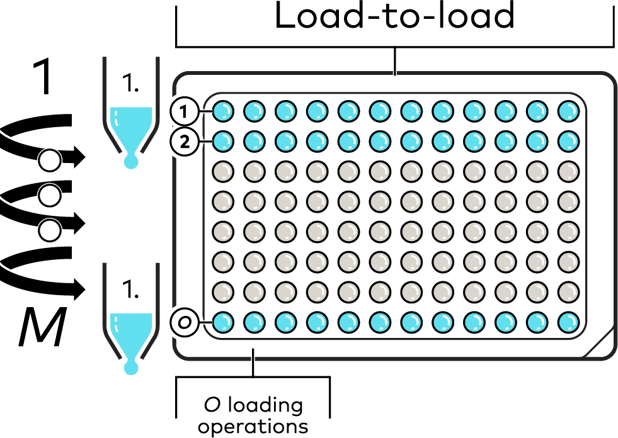

(4) Load-to-load Measurements

Analyzes the sources of error associated with loading operations involving cartridges or disposable tips, for example.

At DISPENDIX, our focus is to bring precision and accuracy in all our products, and we work non-stop to deliver premium liquid handling solutions to our customers.

To learn more about our how our products work, book a demo, or request a quote. Get productive today and help us change the future of health.