Approximately 70% of life science laboratory protocols involve liquid dispensing. Thus, the ability to dispense liquids with pinpoint accuracy is essential in numerous fields, from scientific research and drug discovery to electronics manufacturing and 3D printing. However, achieving precision liquid dispensing is complex and relies on various factors, including selecting the most appropriate tools, optimizing dispensing parameters such as volume, pressure, and time, minimizing waste, and maximizing efficiency.

Here, we will explore the intricacies of achieving consistent, microliter-scale deposits, enabling you to elevate your liquid handling from a technical skill to an art form.

Choosing the Right Tools

Selecting the most appropriate tools is crucial in achieving precision liquid dispensing. The right liquid dispensing tool depends on various factors, including the dispensing technique best sited to the specific needs of a workflow.

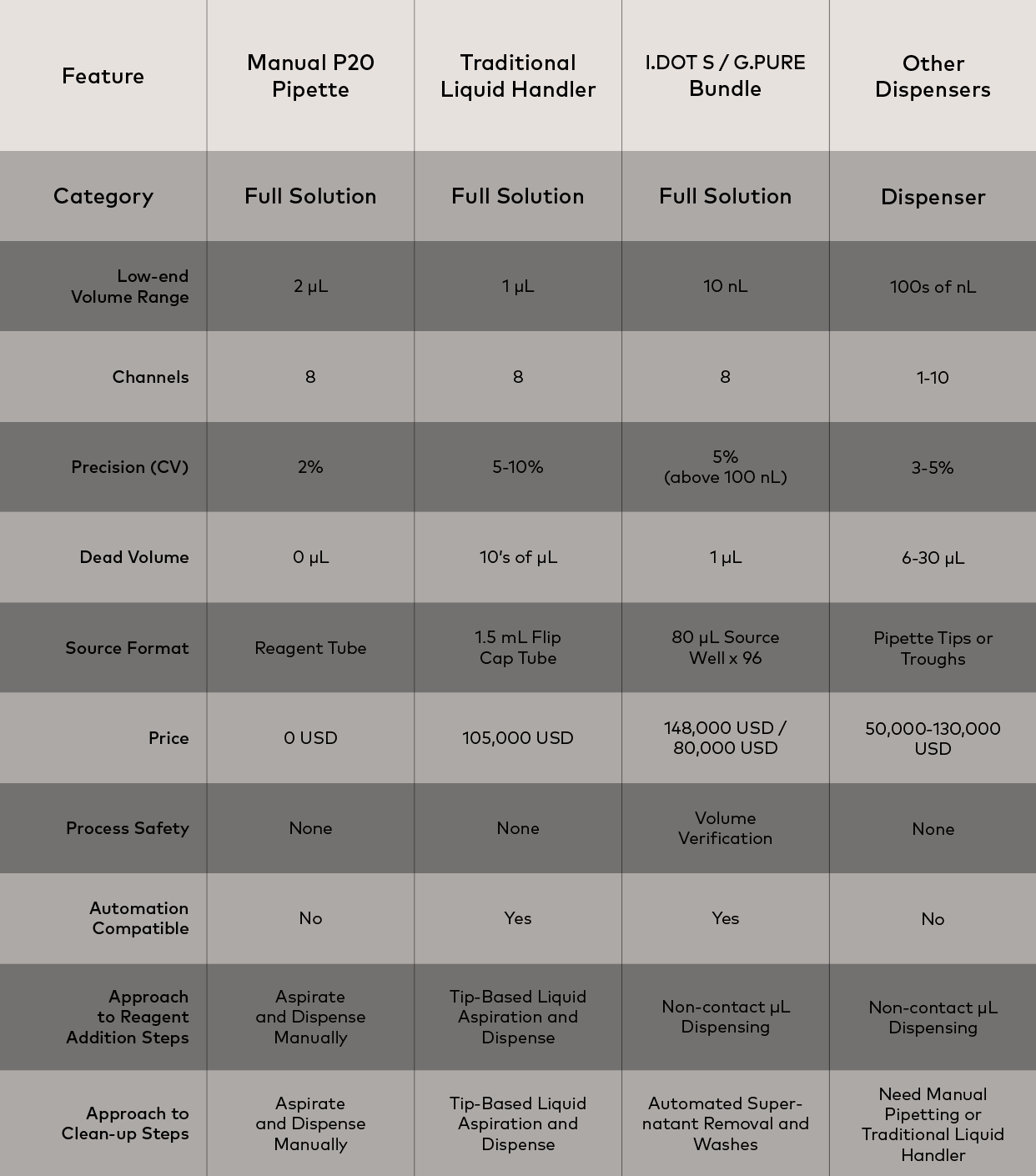

Dispensing techniques include contact dispensers, which physically interact with the liquid and target, and non-contact dispensers, which eliminate the risk of contamination by avoiding direct contact. Meanwhile, acoustic dispensing technology uses ultrasonic energy to eject tiny droplets, ensuring high-precision liquid dispensing and minimizing waste. Air-displacement systems are reliable, versatile systems that leverage a piston mechanism to enable precision liquid dispensing in various applications. After determining the most appropriate dispensing style, the user must choose from manual, semi-automated, and fully automated liquid handling systems (Table 1).

Table 1. Comparison of commonly used liquid handling systems.

A manual liquid dispenser may be the most appropriate system when only a few wells are used. However, for protocols using full 96- or 384-well plates, integrating advanced dispensing systems, like DISPENDIX’s I.DOT Liquid Handler, can significantly enhance operational efficiency and outcome precision1. The I.DOT Non-Contact Dispenser accurately and precisely transfers volumes as low as 4 nL while dramatically reducing dispensing time and reagent and consumable consumption, minimizing waste, and maximizing efficiency2.

Optimizing Dispense Parameters

Once the optimal liquid handling system has been selected, optimizing the dispensing parameters is the next step toward achieving precision liquid dispensing. Key parameters include volume, pressure, speed, and height and are determined by the principles of fluid dynamics, where factors like the liquid's viscosity, surface tension, and density play critical roles in determining the optimal dispensing conditions3.

Dispensing volume is primarily determined by reaction and workflow requirements. However, the working volume of the liquid dispensing system must be considered, as dispensing outside of this will lead to inaccuracies4. Using a system with a low minimum dispensing volume is essential for minimizing sample and reagent waste and enabling assay miniaturization5.

As a general rule of thumb, increasing dispensing speed increases workflow efficiency. However, dispensing speed must be calibrated based on the physical characteristics of the liquid; for example, more viscous liquids, such as glycerol, require slower dispensing speeds than their aqueous counterparts, such as water. This is due to the higher inner friction of viscous molecules, which leads to their low flow rate (Fig. 1).

Figure 1. The I.DOT Liquid Handler facilitates precision liquid pipetting across a full viscosity range from methanol to 65% glycerol.

In manual systems, these parameters are often determined by the operator, requiring rigorous testing and standardized protocols to ensure reproducibility and accuracy6. Conversely, automated and semi-automated systems offer pre-programmed settings to ensure consistent dispensing between users and protocols for more reliable, reproducible results, but the user should also validate these.

By understanding fluid dynamics and optimizing dispensing parameters accordingly, scientists can significantly improve the precision and reliability of liquid handling processes, leading to more consistent and successful outcomes while also minimizing waste and maximizing efficiency.

Conclusion

In conclusion, precision liquid dispensing plays a pivotal role in the life sciences, and achieving such precision relies on selecting the appropriate dispensing tools, optimizing key parameters like volume, pressure, and dispensing time, and implementing strategies to minimize waste and maximize efficiency. Selecting the most suitable liquid handling system can significantly impact liquid handling workflows' accuracy, efficiency, and sustainability. Furthermore, understanding and applying the principles of fluid dynamics allows for the fine-tuning of dispensing parameters, ensuring reproducible and accurate microliter-scale dispensing. Making these considerations can enable users to achieve precision liquid dispensing and enhance the quality and efficiency of laboratory protocols.

Whether you're a seasoned professional or just starting out, choosing DISPENDIX as your liquid handling partner will equip you with the knowledge and techniques to master precision liquid dispensing. Book a demo today!

References

- Kong F, Yuan L, Zheng YF, Chen W. Automatic Liquid Handling for Life Science: A Critical Review of the Current State of the Art. SLAS Technol. 2012;17(3):169-185. doi:10.1177/2211068211435302

- Freese T, Kat R, Lanooij SD, et al. A Guidebook for Sustainability in Laboratories. Chemistry; 2024. doi:10.26434/chemrxiv-2023-g3lmq-v3

- Center of Excellence in Genomic Medicine Research, King Abdulaziz University, Jeddah-21589, Kingdom of Saudi Arabia, Pushparaj P. Revisiting the Micropipetting Techniques in Biomedical Sciences: A Fundamental Prerequisite in Good Laboratory Practice. Bioinformation. 2020;16(1):8-12. doi:10.6026/97320630016008

- Guan XL, Chang DPS, Mok ZX, Lee B. Assessing variations in manual pipetting: An under-investigated requirement of good laboratory practice. J Mass Spectrom Adv Clin Lab. 2023;30:25-29. doi:10.1016/j.jmsacl.2023.09.001

- Nickischer D, Elkin L, Cloutier N, O’Connell J, Banks M, Weston A. Challenges and Opportunities in Enabling High-Throughput, Miniaturized High Content Screening. In: Johnston PA, Trask OJ, eds. High Content Screening. Vol 1683. Methods in Molecular Biology. Springer New York; 2018:165-191. doi:10.1007/978-1-4939-7357-6_11

- Taylor PB, Ashman S, Baddeley SM, et al. A Standard Operating Procedure for Assessing Liquid Handler Performance in High-Throughput Screening. SLAS Discov. 2002;7(6):554-569. doi:10.1177/1087057102238630