Precision and efficiency are central tenets of scientific workflows, and they become especially important in workflows involving numerous liquid handling tasks. Often, automation engineers are tasked with building automated pipelines for highly complex scientific workflows involving numerous liquid handling steps. While traditional liquid handling devices have the capacity to perform liquid handling, they are often limited in terms of precision and efficiency. Low-volume, non-contact liquid dispensers represent a potential solution for improving precision and efficiency in complex workflows.

Here, we discuss the essential role of reagent dispensing in scientific workflows, compare liquid handling solutions, and highlight key factors that should be considered by automation engineers when choosing liquid handling solutions for automated workflows.

The Role of Liquid Handling in Scientific Workflows

Liquid handling, the process of reformatting, transferring, and dispensing liquid solutions, is an essential part of all scientific workflows. Liquid handling solutions have evolved drastically from the early days of mouth pipetting to the recent emergence of advanced automated pipetting technology1–3. Automated pipetting technologies are innovative liquid handling solutions that come with several advantages over manual pipetting, including:

- Higher precision and accuracy

- Increased efficiency

- Improved safety and ergonomics

These important advantages make automated liquid handling solutions an essential component of scientific workflows, particularly complex, multi-step, or high-throughput pipelines3,4.

Traditional Liquid Handlers vs. Non-Contact Dispensers

Automated liquid handling solutions can be classified into traditional liquid handlers and non-contact dispensers. Traditional liquid handlers rely on air displacement mechanisms to dispense liquid through disposable tips5. While using fresh sterile tips at each step is essential for minimizing the contamination risk, it also leads to high consumable expenditure and slows down the workflow. Moreover, the range is generally smaller, and the use of tips means there tends to be a low degree of accuracy at lower volumes.

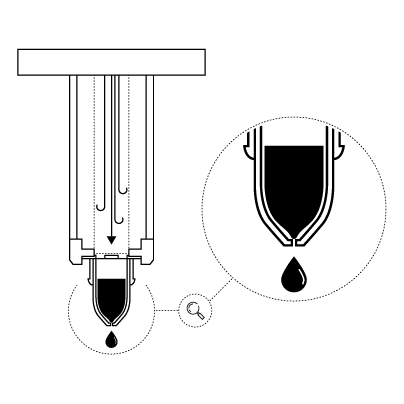

On the other hand, a non-contact liquid handling or dispensing system utilizes an air pressure and droplet ejection mechanism to dispense liquid through a pore (Fig. 1)5. For example, DISPENDIX’s I.DOT Non-Contact Dispenser has precisely molded consumable source wells containing a 600, 100, or 200 μM pore. It is equipped with individually controlled positive pressure channels, which apply precisely controlled pressure pulses to the consumable source wells, leading to droplet dispensing into the target plate.

Figure 1. Non-contact dispensers, like the I.DOT Liquid Handler, utilize a specific droplet ejection mechanism for tip-free liquid dispensing.

Non-contact liquid dispensers have several advantages over traditional contact dispensers, including:

- Enhanced accuracy and precision. The I.DOT Liquid Handler can accurately dispense volumes as low as 8 nL, and DropDetection sensors enable verification of actual droplets dispensed (Fig. 2).

- Low dead volume. The I.DOT Liquid Handler requires only 1 μL of dead volume per dispense, which, together with high accuracy at low volumes, facilitates assay miniaturization.

- Improved speed. The I.DOT is capable of dispensing 10 nL across a 96-well plate in only 10 seconds or across a 384-well plate in only 20 seconds. This improves assay efficiency and enables high-throughput workflows.

- Tipless transfers. The non-contact nature of liquid transfers means that pipette tips are not required, making non-contact dispensing more sustainable than traditional methods requiring new pipette tips for every dispense.

- Minimizes contamination risk. The non-contact dispensing design eliminates the risk of carryover and cross-contamination.

Figure 2. DropDetection sensors count droplets dispensed by the I.DOT Non-Contact Dispenser to ensure accurate dispensing.

Considerations for Workflow Implementation

For automation engineers, there are a number of considerations that should be made when selecting the most appropriate liquid handling solutions for automating a complex experimental pipeline.

- Break down your workflow to identify liquid handling steps. Detailing each step of the pipeline will enable identification of the number of types of liquid handling steps, as well as critical points, such as those requiring specialized handling.

- Analyze your liquid handling requirements. This step involves assessing volume ranges and throughput requirements, as well as accuracy, precision, and reagent and sample conservation needs. This will help determine if a low-volume non-contact dispenser is necessary for the project, i.e., to enable accurate low-volume dispensing or to minimize dead volumes when working with precious samples or expensive reagents.

- Consider budget, investment, and operational costs. While non-contact dispensers may have a higher upfront cost, they may lead to long-term savings from reduced consumable use (e.g., pipette tips) and improved efficiency.

- Assess integration and compatibility. Some liquid handling solutions, like the I.DOT Non-Contact Dispenser, have the technology to integrate with other systems for improved workflow automation as well as seamless data transfer. This can be useful for improving workflow efficiency, reducing human input requirements, and ensuring that data is secure and compliant with regulatory requirements.

- Consider potential future use. When developing an automation pipeline, the future usefulness of liquid handling solutions also needs to be considered. It is essential to ensure that the system can be adapted in line with protocol changes and scaled up to meet increased throughput demands. This flexibility should also extend to new users: user-friendly systems requiring minimal training can be implemented more quickly and can accommodate future staff turnover.

Conclusions

Low-volume non-contact dispensers have emerged as a liquid handling solution capable of addressing the need for precision and efficiency within scientific workflows, especially those encompassing complex liquid handling tasks. These dispensers present a viable solution to the challenges associated with traditional liquid handling systems, including compromised accuracy and excessive, unsustainable use of consumables, and should be considered by automation engineers in the development of automation pipelines.

At DISPENDIX, we wholeheartedly advocate for the integration of low-volume non-contact dispensers into every automation enthusiast's arsenal. These dispensers are not merely tools; they are catalysts for scientific progress, enabling researchers to push the boundaries of knowledge with unparalleled precision and efficiency.

Embrace the power of automation and let low-volume, non-contact dispensers propel your research to new heights. Schedule a workflow consultation today!

References

- DeLuca C, Gioeli RP, Yarm SD. Elimination of mouth pipetting in the tissue culture laboratory. J Tissue Cult Methods. 1980;6(1):21-23. doi:10.1007/BF01665900

- Klingenberg M. When a common problem meets an ingenious mind: The invention of the modern micropipette. EMBO Rep. 2005;6(9):797-800. doi:10.1038/sj.embor.7400520

- Torres-Acosta MA, Lye GJ, Dikicioglu D. Automated liquid-handling operations for robust, resilient, and efficient bio-based laboratory practices. Biochem Eng J. 2022;188:108713. doi:10.1016/j.bej.2022.108713

- Tegally H, San JE, Giandhari J, De Oliveira T. Unlocking the efficiency of genomics laboratories with robotic liquid-handling. BMC Genomics. 2020;21(1):729. doi:10.1186/s12864-020-07137-1

- Chai SC, Goktug AN, Chen T. Liquid handling devices in drug discovery – when, what, why? Eur Pharm Rev. 2013;18(6):11-14.