Understanding tumor behavior and developing effective treatments is hindered by the limitations of traditional 2D cell cultures, which fail to replicate the complex, dynamic environment of real tumors. This disconnect often leads to promising drug candidates failing in clinical trials. Consequently, researchers are turning to 3D bioprinting, a technology that allows precise control over cell arrangement and biomaterial composition, to create realistic tumor models that mimic the in vivo microenvironment.

This Advances in 3D Bioprinting for Cancer Biology and Precision Medicine: From Matrix Design to Application, by researchers from the Children's Cancer Institute and the Australian Centre for NanoMedicine, explores the intricacies of the tumor microenvironment and the key factors to consider when bioprinting these models. It delves into different bioprinting techniques and the selection of biomaterials, both natural and synthetic. Finally, it showcases existing bioprinted tumor models and highlights the potential of this technology to revolutionize clinical applications in cancer research and personalized medicine.

Potential Clinical Applications: Biobanks and In Vitro Drug Screening for Guided Therapy

While 3D tumor models hold great promise for drug development and personalized medicine, their current use in clinical studies lags behind. Traditional methods like manual spheroid formation and Matrigel embedding dominate, despite their limitations in terms of tissue availability, viable cell numbers, and scalability.

The lack of readily available patient samples and the slow development time of PDX (patient-derived xenograft) models further hinder research progress. The advent of bioprinting offers a potential solution with its ability to rapidly generate and biobank large collections of tumor organoids. Studies have shown success in establishing biobanks with varying success rates (38.6% - 100%), but the time required (4-13 weeks) often clashes with patient treatment schedules.

Bioprinting's high throughput and reproducibility can overcome these challenges. Its ability to handle large data volumes increases the chances of successful drug screening. Several research groups have already developed a simple and cost-effective miniaturized cell culture system that can print precise numbers of cells in nanoliter-range droplets, whether manually or using the I.DOT Liquid Handler, mimicking patient tumor heterogeneity. The system can print roughly 100 cells in a tiny droplet of liquid, 100 nL volume per spot, and requires a certain concentration of cells to be used (Video 1).

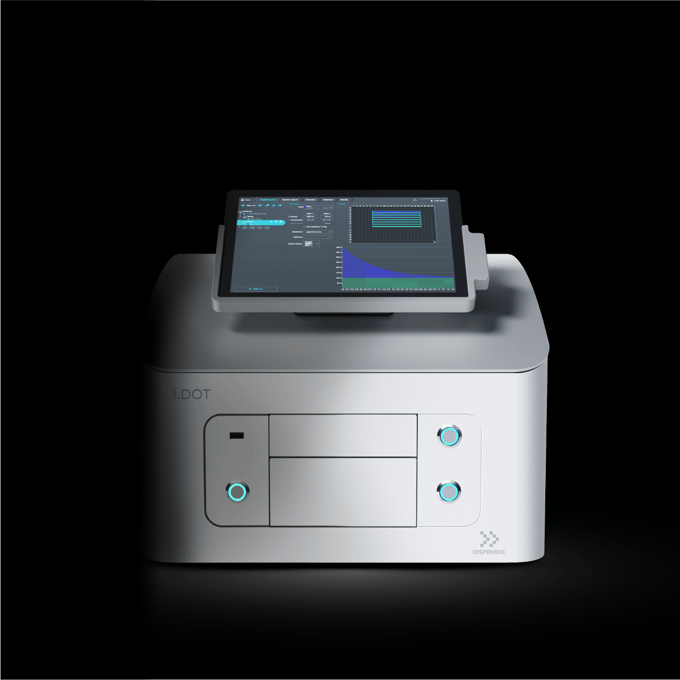

Recent improvements to the technology allow for printing a precise number of cells and even smaller droplets, making it possible to use the system in multi-well plates for research and experiments. Real-time droplet counting by I.DOT Non-contact Dispenser provides accurate dispense volume, eliminating guesswork and maximizing efficiency. Every drop is accounted for, right before your eyes.

Bioprinting platforms can control the culture environment using tunable bioinks, helping to maintain the original genetic stability of cells. This integration of bioprinting for production, expansion, biobanking, and drug screening of tumoroids holds significant potential for improving clinical outcomes and personalized medicine.

Conquer Cancer Research with Precision

Breakthroughs in cancer research demand cutting-edge tools. The I.DOT Non-Contact Dispenser from DISPENDIX isn't just another instrument; it's a revolution in precision dispensing for tumor organoid research.

Unleash the power of bioprinting: Generate intricate 3D tumor models with single-cell accuracy, replicating the complex microenvironment that traditional methods simply can't match.

Fast-forward drug discovery: Screen an avalanche of potential therapies on miniaturized, personalized organoid arrays, accelerating the path to effective treatments.

Save precious samples: With nanoliter-scale dispensing and assay miniaturization, minimize waste and maximize your research potential, even with limited patient tissue.

Boost reproducibility: Say goodbye to variability and hello to consistent, reliable results, thanks to the I.DOT's unparalleled precision and control.

The I.DOT isn't just a liquid handler; it's a drug discovery game-changer. Choose the I.DOT Liquid Handler and unlock the full potential of your research. Schedule a workflow consultation and take the first step towards a healthier tomorrow.

References

M. Jung, S. Ghamrawi, E. Y. Du, J. J. Gooding, M. Kavallaris, Advances in 3D Bioprinting for Cancer Biology and Precision Medicine: From Matrix Design to Application. Adv. Healthcare Mater. 2022, 11, 2200690. https://doi.org/10.1002/adhm.202200690