In the fast-paced world of scientific research, precision, efficiency, and sustainability are crucial for success. While still widely used, traditional manual liquid handling methods come with significant limitations, including high variability, low throughput, and excessive waste1. The I.DOT Liquid Handler from DISPENDIX is an innovative, automated liquid handling solution that addresses these challenges head-on. With its advanced features and unparalleled accuracy, the I.DOT Liquid Handler is transforming laboratory workflows and empowering researchers to achieve more. This article explores the challenges of manual liquid handling and highlights the features that make the I.DOT Liquid Handler a standout solution for modern biological workflows.

Challenges in Traditional Handling

Manual liquid handling processes are plagued with challenges that put experimental success at risk. Even skilled researchers can make pipetting errors, and user variability complicates replication, making it challenging for scientists to collaborate and draw reliable conclusions2,3. Manual methods are inherently low throughput, especially when compared to more modern liquid handling techniques4,5. This means that research projects drag on, and researchers spend countless hours pipetting multi-well plates, putting themselves at risk of repetitive strain injury6.

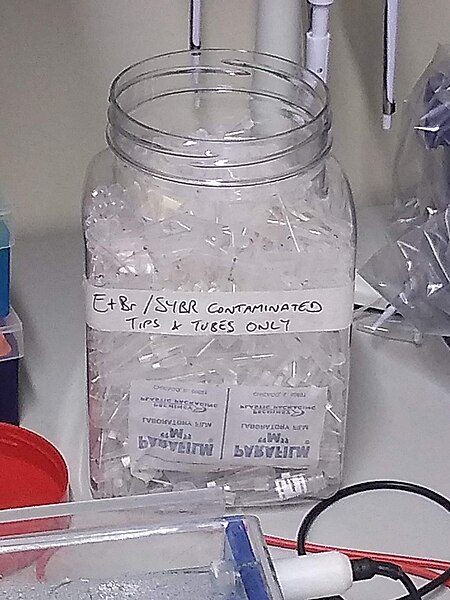

Manual pipetting produces mountains of pipette tip waste, and dispensing errors squander costly reagents and necessitate repeat experiments and extensive troubleshooting (Fig. 1). This not only leads to even more plastic waste but also means that reagents need to be repurchased7,8. Moreover, manual dispensing methods mean these reagents must be used at an inefficient scale that is not optimized for sustainability or tight laboratory budgets.

Figure 1. Manual pipetting generates enormous amounts of pipette tip waste and can expose researchers to harmful chemicals. (Source)

The I.DOT Liquid Handler from DISPENDIX has emerged as an all-in-one solution to the challenges of traditional handling techniques by providing an automated, contactless, scalable liquid handling solution.

What Makes the I.DOT Unique?

Core Features

The I.DOT stands out among other dispensers because of its non-contact liquid handling technology and ultra-low volume dispensing, which makes it capable of dispensing volumes as low as 8 nL. Non-contact dispensing massively reduces the chances of contamination and the need for disposable plastics. Contamination from microbes or improperly dispensed reagents can jeopardize workflows and entire projects9. The I.DOT effectively eliminates these risks.

Advantages

The I.DOT boasts unrivaled precision and accuracy, with 1 μL dead volume, making it great for sensitive, high-cost techniques like next-generation sequencing (NGS). The I.DOT’s ability to dispense low volumes allows workflows to be scaled down, reducing costs by minimizing the use of excess reagents and enabling more efficient, waste-free experimental throughput. Furthermore, the I.DOT supports a range of liquid viscosities from methanol to 65% glycerol, which means it can support various applications, including genomics, proteomics, and drug discovery, at the nanolitre scale.

Real-World Applications of the I.DOT

High-Throughput Screening

The I.DOT allows high-throughput techniques to reach their full potential by dramatically increasing dispensing speed over traditional methods while improving accuracy. It allows researchers to perform other tasks while securing robust, reproducible data they can trust. The I.DOT can dispense 384 source liquids per run, meaning the only limitation for experimental design is the researcher’s imagination.

PCR Setup and NGS Library Preparation

PCR and NGS success hinge on the accurate dispensing of minute volumes. This is especially true in experiments that use precious patient samples, which are often low-volume. The I.DOT Liquid Handler simplifies tedious NGS library prep workflows and ensures researchers get the most out of their samples at a scale that supports resource and sample efficiency.

Assay Development and Optimization

Designing and setting up assays can be a complex and demanding task10. The last thing researchers need is to worry about whether their assay is failing because of variability in their own pipetting. The I.DOT reduces user variability, enabling researchers to focus on refining assay design and achieving optimization more quickly than with traditional methods.

Impact on Laboratory Efficiency and Sustainability

One area where the I.DOT Liquid Handler shines, especially for the environmentally-minded scientist, is its impact on reducing waste and contributing to more sustainable laboratory practices (Fig. 2). The I.DOT’s contactless dispensing and scalability mean that researchers need to purchase lower reagent volumes for their experiments and don’t need to worry about cross-contamination. The I.DOT uses significantly fewer pipette tips than manual pipetting and other automated technologies. This means less waste and more sustainable research.

Figure 2. The I.DOT Liquid Handler ensures that researchers only use a fraction of the pipette tips of other approaches, reducing both plastic waste and overall laboratory costs.

Why Choose the I.DOT?

Simply put, the I.DOT enables scientists to complete workflows much faster than traditional methods, accelerating project completion and giving researchers a competitive edge. Furthermore, this speed advantage does not come at the expense of quality. On the contrary, the I.DOT Liquid Handler delivers exceptional accuracy, enabling researchers to achieve reliable results, drive innovation in their field, and streamline the development of groundbreaking technologies.

Conclusion

The I.DOT Non-Contact Dispenser is a game-changer for laboratories aiming to optimize efficiency, accuracy, and sustainability. By eliminating the inefficiencies and errors of manual pipetting, the I.DOT accelerates workflows, reduces waste, and enhances experimental reliability. For researchers looking to stay ahead in their fields, the I.DOT offers a powerful tool to unlock their full potential and drive the future of science with confidence and precision.

Learn more about the I.DOT Liquid Handler and how it can transform your lab’s workflows. Download the I.DOT brochure now!

References

- Holland I, Davies JA. Automation in the Life Science Research Laboratory. Front Bioeng Biotechnol. 2020;8(571777). doi:10.3389/fbioe.2020.571777

- Guan XL, Chang DPS, Mok ZX, Lee B. Assessing variations in manual pipetting: An under-investigated requirement of good laboratory practice. J Mass Spectrom Adv Clin Lab. 2023;30:25-29. doi:10.1016/j.jmsacl.2023.09.001

- Lippi G, Lima-Oliveira G, Brocco G, Bassi A, Salvagno GL. Estimating the intra- and inter-individual imprecision of manual pipetting. Clinical Chemistry and Laboratory Medicine (CCLM). 2017;55(7). doi:10.1515/cclm-2016-0810

- Hansel CS, Plant DL, Holdgate GA, Collier MJ, Plant H. Advancing automation in high-throughput screening: Modular unguarded systems enable adaptable drug discovery. Drug Discov Today. 2022;27(8):2051-2056. doi:10.1016/j.drudis.2022.03.010

- Hess JF, Kohl TA, Kotrová M. Library preparation for next generation sequencing: A review of automation strategies. Biotechnol Adv. 2020;41(107537). doi:10.1016/j.biotechadv.2020.107537

- Wu JZ, Sinsel EW, Shroyer JF, et al. The musculoskeletal loading profile of the thumb during pipetting based on tendon displacement. Medical Engineering & Physics. 2013;35(12):1801-1810. doi:10.1016/j.medengphy.2013.08.004

- Alves J, Sargison FA, Stawarz H. A case report: insights into reducing plastic waste in a microbiology laboratory. Access Microbiol. 2021;3(3). doi:10.1099/acmi.0.000173

- Bistulfi G. Reduce, reuse and recycle lab waste. Nature. 2013;502(7470):170-170. doi:10.1038/502170a

- Strong MJ, Xu G, Morici L, et al. Microbial Contamination in Next Generation Sequencing: Implications for Sequence-Based Analysis of Clinical Samples. Rall GF, ed. PLoS Pathog. 2014;10(11):e1004437. doi:10.1371/journal.ppat.1004437

- Jones J, Zhang B, Zhang X, et al. Quality by Design for Preclinical In Vitro Assay Development. Pharmaceutical Statistics. Published online September 24, 2024:pst.2430. doi:10.1002/pst.2430