The Comprehensive Guide to DISPENDIX Product Innovations, Values, & Impact

Discover how DISPENDIX devices enhance workflows by providing precise dispensing, miniaturization, low dead volume, and a walkup-friendly design.

Struggling with tedious NGS library prep? DISPENDIX's I.DOT & G.PURE automate 80% of the process, boosting accuracy, efficiency & saving costs.

Every step in the NGS (next-generation sequencing) library preparation process involves adding microliter scale volumes of reagents to nucleic acid samples. In fact, up to 80% of the library preparation process can be automated by a reagent dispenser.

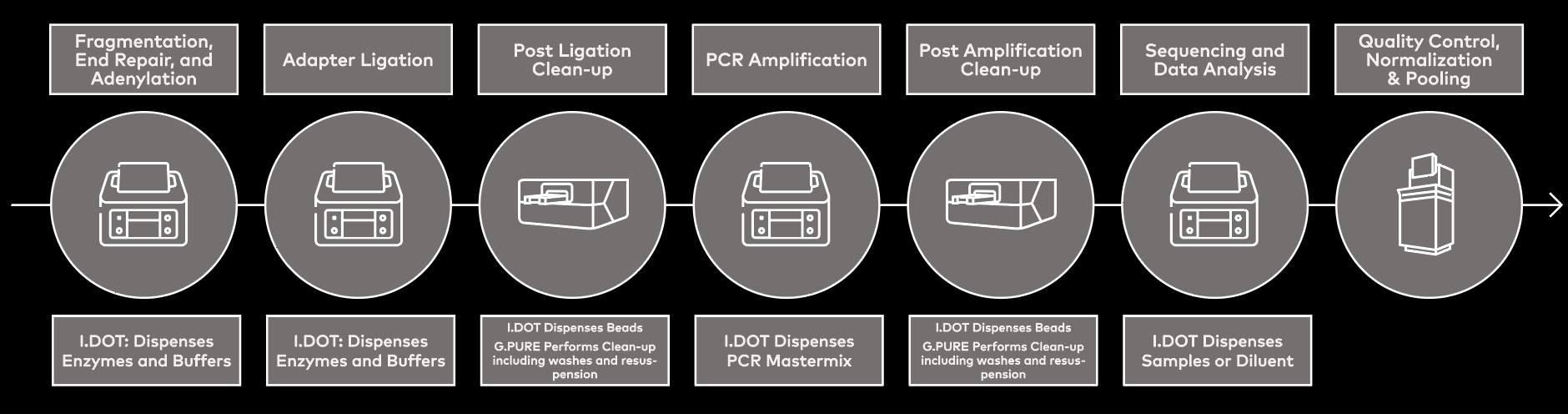

At DISPENDIX, we have designed the perfect reagent dispenser for NGS. The I.DOT Liquid Handler allows researchers to dispense microliter scale volumes of enzymes, buffers, and beads to samples throughout the library preparation process with the click of a button (Fig. 1).

Figure 1. Workflow schematic showing where the I.DOT Liquid Handler and G.PURE Clean-up Device fit into the NGS library preparation workflow.

For clean-up steps in the process, The G.PURE Clean-Up Device is a device designed to automate bead-based clean-ups, the most tedious steps in the NGS library preparation process. The G.PURE provides a user-friendly alternative to complex automation and error-prone manual pipetting. Using an integrated dispenser and novel centrifugal evacuation technology, the product enables fast, reproducible, and tip-free bead washes and resuspension (Fig. 1).

You can be sure that you will generate trustworthy results. The I.DOT dispenses 50 nL-10 μL within 5% accuracy and CV. Dispense with insight into the actual volume dispensed every time with integrated volume verification. Built-in volume verification via DropDetection (i.e., droplet counting) provides process safety. If your source runs out of liquid, you will know, and the instrument can recover using the “re-dispense missed droplets” feature.

The G.PURE guarantees high yield and purity clean-ups with limited manual intervention.

Accuracy and precision are achieved out of the box. Anyone can easily use the instruments to program and run a 1 μL dispense or bead-based clean-up across a 96- or 384-well plate in under a minute.

The I.DOT and G.PURE are appliances that automate the reagent dispensing and bead clean-up steps of the NGS process. NGS is approximately 70% reagent dispensing, 20% clean-ups, and 10% temperature management. You get most of the workflow automated for a super low barrier to entry with the I.DOT and G.PURE products.

When investing in a full solution from DISPENDIX, we provide standardized and tested methods for automating even the most complex NGS library preparation protocol.

The I.DOT enables you to dispense reagents with a 1 μL dead volume and run more samples for the same reagent cost. The I.DOT also enables the ability to miniaturize easily. The DISPENDIX team has worked through miniaturization of even the most complex NGS workflows and can help you to scale volumes as low as 1/10th the manufacturer's recommended SOP without compromising data quality.

Additionally, you will use a fraction (literally) of the pipette tips required by traditional automation, save the planet, and retain your budget. DISPENDIX has miniaturized dozens of NGS kits and can help you to optimize your kit of choice.

Forget about training. The I.DOT and G.PURE can be run by anyone regardless of automation experience! We believe that software for dispensing a constant volume, a dilution, normalization, and pooling should not be complicated – so our software, Assay Studio, isn't.

By utilizing the I.DOT and G.PURE in your lab, you can empower your research assistants and lab technicians to redirect their focus towards the core of their work: the science itself! With the automation of reagent dispensing and bead clean-up steps, these innovative tools alleviate the burden of manual tasks, allowing your team to delve deeper into experimental design, data analysis, and the pursuit of groundbreaking discoveries.

By streamlining workflow processes and minimizing the potential for human error, the I.DOT and G.PURE enable your team to unleash their creativity and expertise in the pursuit of scientific advancement. Let your team's passion for science shine through, unencumbered by tedious manual tasks, and watch as innovation flourishes in your lab.

NGS kits come ready with a standard operating procedure straight out of the box, streamlining the process of understanding the liquid handling workflow once you've become acquainted with the kit. DISPENDIX has miniaturized dozens of NGS kits and can help you to optimize your kit of choice.

The innovative I.DOT and G.PURE systems have been meticulously crafted with adaptability in mind, guaranteeing a seamless transition to any application they encounter. Their flexibility allows for effortless integration into various workflows, making them an indispensable tool for any laboratory or research setting.

Gone are the days of manually pipetting in 384 wells, a task that is not only horrendous but also prone to errors. The I.DOT and G.PURE are here to revolutionize your lab's workflow and ensure that precision and efficiency are at the forefront of your NGS processes. By implementing these cutting-edge automation tools, your lab will not only save time but also generate more value from the accuracy and reliability of the I.DOT and G.PURE.

Say goodbye to the stress of user errors and the headache of error recovery – with these innovative instruments, your lab will thrive like never before.

The DISPENDIX team has worked through miniaturization of even the most complex NGS workflows and can help you to scale volumes as low as 1/10th the manufacturer's recommended SOP without compromising data quality. Additionally, use a fraction (literally) of the pipette tips required by manual pipetting and traditional automation, save the planet, and retain your budget. DISPENDIX has miniaturized dozens of NGS kits and can help you to optimize your kit of choice.

Forget about training. Our instruments do not require any automation expertise to reliably use. The I.DOT and G.PURE can be run by anyone regardless of automation experience! We believe that software for dispensing a constant volume, dilution, normalization, and pooling should not be complicated – so our software, Assay Studio, isn't. Anyone in your lab at any skill level can program and run microliter scale dispenses and bead-based clean-ups in a 384-well plate and the data will be reliable.

Choosing between a fully automated and semi-automated NGS workflow involves evaluating several trade-offs based on your specific needs and resources. Here's a breakdown of the key factors:

Fully Automated NGS Workflow:

Pros:

Cons:

Semi-Automated NGS Workflow:

Pros:

Cons:

The best choice depends on your specific needs and priorities. Consider factors like:

Watch as your research endeavors soar to new heights with the I.DOT Non-Contact Dispenser and G.PURE Clean-Up Device by your side. Book a demo today!

Discover how DISPENDIX devices enhance workflows by providing precise dispensing, miniaturization, low dead volume, and a walkup-friendly design.

Learn how the DISPENDIX I.DOT Liquid Handler and G.PURE NGS Clean-Up Device improve genomic workflows by boosting efficiency, accuracy, and sample...

The I.DOT Liquid Handler empowers researchers with reliable dose response curves for informed decision-making.