Precise and efficient liquid dispensing is crucial in various fields, from scientific research to manufacturing. Optimizing liquid dispensing processes can help scientists boost accuracy, consistency, and efficiency in their workflows and resulting data1,2. However, optimized liquid dispensing processes rely on several factors, such as choosing the right dispensing system and style, optimizing dispensing parameters, and minimizing waste. Here, we will explore fundamental strategies for achieving optimized liquid dispensing and discuss its impact on various applications.

Benefits of Optimized Liquid Dispensing

Liquid dispensing is critical to many experimental workflows spanning fundamental research, clinical research, drug discovery, and manufacturing. Optimized liquid dispensing has several benefits for the user, including:

- Accurate, consistent results

Optimizing liquid dispensing minimizes human error and variability and leads to precise liquid dispensing. This ensures that experiments are reproducible and data is reliable, which is critical for validating and accurately interpreting findings3.

- Enhanced efficiency and productivity

Optimized liquid dispensing processes streamline laboratory workflows, allowing scientists to perform complex protocols faster and with less manual intervention4. This frees researchers to focus on tasks requiring their skills and experience, such as data interpretation, accelerating scientific discovery and diagnostics, and maximizing profits in manufacturing environments.

Optimized liquid dispensing systems minimize sample, reagent, and consumable usage by dispensing precise volumes. This conserves valuable resources, cuts costs, and supports environmental sustainability5.

Strategies to Achieve Optimized Liquid Dispensing

Optimized liquid handling undeniably offers many benefits, emphasizing the importance of adopting best practices. By applying the following strategies when developing liquid handling workflows, users can achieve the advantages of optimized liquid dispensing.

Choosing the Right Dispensing Style

When developing an optimized liquid dispensing strategy, users should first determine the dispensing style that best aligns with the requirements of their specific workflow. Each dispensing technique offers unique advantages relevant to different applications. For example, contact dispensers physically touch the liquid to the target, while non-contact dispensers dispense liquids without contacting the target, minimizing the risk of contamination. Acoustic dispensing technology employs ultrasonic energy to eject minute droplets from a liquid surface, offering unparalleled accuracy and minimal waste, while air-displacement systems utilize a piston and are widely used for their versatility and reliability.

Selecting the Optimal Liquid Handling System

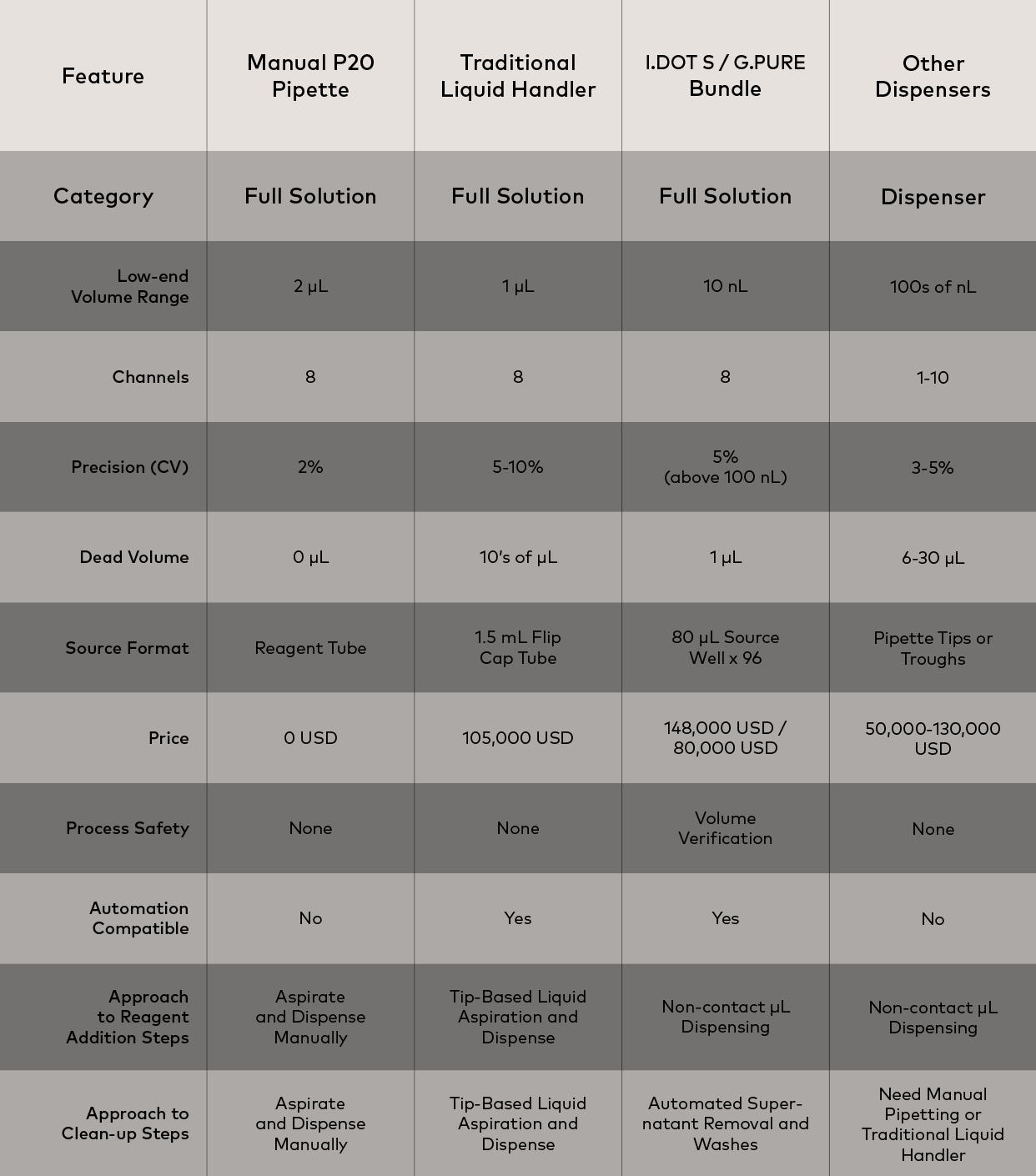

Once the optimal dispensing style has been defined, users must select the right liquid handling equipment to meet their needs. Dispensing systems comprise manual, semi-automated, and fully automated systems, each with pros and cons, as summarized in Table 1. The user's and project's unique goals and requirements will determine the optimal liquid dispensing system.

Table 1. Comparison of available liquid handling systems.

Optimizing Dispensing Parameters

Once the dispensing style and system have been selected and integrated into new or existing workflows, dispensing parameters can be optimized. This includes optimizing the liquid dispensing speed, pressure, height, and angle. The user will largely determine these for manual systems, but they should still be considered, testing performed, and standardized protocols implemented where possible6. However, optimized liquid dispensing parameters can be programmed into automated, electronic, or robotic systems to facilitate consistency. Ideally, these should be defined based on liquid classification. For example, a slower speed is recommended for viscous liquids compared to aqueous solutions1. Finally, some advanced liquid handling tools have blow-out and mixing options, which can further improve dispensing accuracy and efficiency.

Minimizing Waste

Minimizing waste is an essential but often overlooked component of optimized liquid dispensing. Not only is it important for reducing costs and enhancing laboratory sustainability, but it also facilitates the use of lower sample volumes, which is necessary when conducting experiments with precious patient samples7,8.

Devices with fixed tips provide consistent performance and eliminate the need for tip changes, reducing plastic waste and operational time. Conversely, changeable tip systems are more flexible and minimize contamination risks, essential in multiplex assays or when handling multiple reagents. Non-contact dispensers eliminate the need for tips altogether, acting as a sustainable solution that minimizes plastic use and removes the risk of cross-contamination. In addition to reducing tip waste, minimizing sample waste is also crucial. Opting for automated systems with low dead volumes and minimal end-volume ranges presents an ideal approach. For example, DISPENDIX’s I.DOT Liquid Handler (Fig. 1) has a dead volume of 1 μL and accurately dispenses volumes as low as 4 nL, rendering it compatible with assay miniaturization.

Figure 1. DISPENDIX’s I.DOT Non-Contact Dispenser offers a sustainable, tip-free solution ideal for eco-conscious scientists.

Conclusion

In conclusion, achieving optimized liquid dispensing requires the selection of the most appropriate dispensing styles and systems, meticulous adjustment of dispensing parameters, and a commitment to waste reduction. By following these guidelines, researchers can significantly enhance their workflows' precision, efficiency, and sustainability. Whether in academic research, clinical diagnostics, drug discovery, or manufacturing, the principles of optimized liquid dispensing play a pivotal role in enhancing the reliability and integrity of scientific outcomes.

Need help optimizing your specific dispensing application? Our team of application experts is here to assist you. Book a demo or schedule a workflow consultation today!

References

- Torres-Acosta MA, Lye GJ, Dikicioglu D. Automated liquid-handling operations for robust, resilient, and efficient bio-based laboratory practices. Biochem Eng J. 2022;188:108713. doi:10.1016/j.bej.2022.108713

- Kong F, Yuan L, Zheng YF, Chen W. Automatic Liquid Handling for Life Science: A Critical Review of the Current State of the Art. SLAS Technol. 2012;17(3):169-185. doi:10.1177/2211068211435302

- Hentz NG, Knaide TR. Effect of Liquid-Handling Accuracy on Assay Performance. SLAS Technol. 2014;19(2):153-162. doi:10.1177/2211068213504095

- Tegally H, San JE, Giandhari J, De Oliveira T. Unlocking the efficiency of genomics laboratories with robotic liquid-handling. BMC Genomics. 2020;21(1):729. doi:10.1186/s12864-020-07137-1

- Freese T, Kat R, Lanooij SD, et al. A Guidebook for Sustainability in Laboratories. Chemistry; 2024. doi:10.26434/chemrxiv-2023-g3lmq-v3

- Taylor PB, Ashman S, Baddeley SM, et al. A Standard Operating Procedure for Assessing Liquid Handler Performance in High-Throughput Screening. SLAS Discov. 2002;7(6):554-569. doi:10.1177/1087057102238630

- Kricka LJ, Park JY, Li SF, Fortina P. Miniaturized detection technology in molecular diagnostics. Expert Rev Mol Diagn. 2005;5(4):549-559. doi:10.1586/14737159.5.4.549

- Kiechle FL, Holland CA. Point-of-Care Testing and Molecular Diagnostics: Miniaturization Required. Clin Lab Med. 2009;29(3):555-560. doi:10.1016/j.cll.2009.06.013