Next-generation sequencing (NGS) emerged in the early 2000s as a pivotal technology for genetic analysis, enabling the rapid sequencing of DNA and RNA much more time- and cost-effectively than traditional Sanger sequencing1,2. The significant benefits of NGS technologies have bolstered genomics research and influenced clinical applications, driving notable advancements in rare disease diagnostics and personalized medicine3,4. Despite its potential, NGS workflows are fraught with challenges. Notably, the manual library preparation stage of NGS workflows is a time-consuming and laborious process prone to human error and variability, which can lead to discrepancies in the resulting data5. Moreover, its manual nature limits throughput and scalability, representing a barrier to many potential applications. However, NGS liquid dispensing automation has emerged as a solution to these challenges5. Here, we will discuss the benefits of automation in NGS library preparation and explore how automation can be seamlessly integrated into existing NGS workflows.

Benefits of Automation

Applying automated NGS liquid dispensing has numerous advantages over manual processes5, including:

Increased Efficiency and Throughput

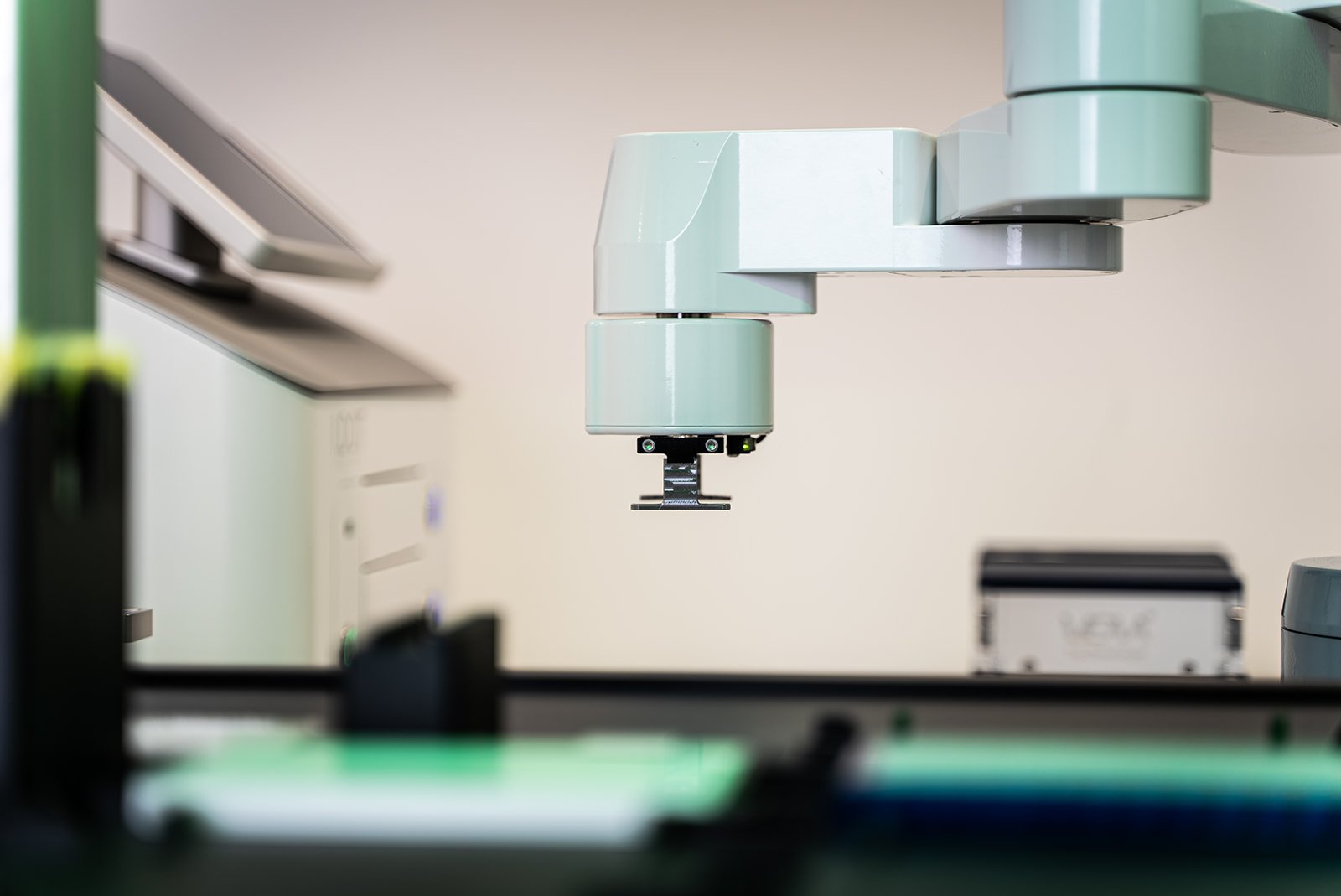

Automation allows for the simultaneous processing of multiple samples (Fig. 1). This significantly increases the throughput and speed of NGS workflows, making it feasible to handle large-scale sequencing projects within shorter timeframes and enhancing overall laboratory productivity. This is especially useful for high-throughput screening (HTS) workflows, commonly used in translational research and drug discovery6.

Figure 1. Automated NGS liquid handling for library preparation increases the number of samples that can be sequenced in parallel.

Improved Accuracy and Reproducibility

Automated NGS liquid dispensing delivers precise volumes of reagents, minimizing the variability associated with manual pipetting. Moreover, automated systems eliminate the risk of human error, which can lead to inaccurate, inconsistent, and unreliable results in highly sensitive sequencing workflows7.

Cost Savings

Notwithstanding the relatively high initial costs of automated setups, automating NGS liquid dispensing workflows can lead to substantial savings in the long run. First, automated systems' high precision and low dead volume minimizes reagent and pipette tip use, reducing waste, especially in high-throughput settings. This also makes NGS workflows compatible with assay miniaturization, facilitating NGS even when limited patient samples are available8. Moreover, by automating labor-intensive steps, researchers can shift their focus to tasks that require critical thinking and expertise.

Enhanced Safety

Automated NGS liquid dispensing systems limit exposure to hazardous chemicals or biological materials. Moreover, by automating repetitive pipetting tasks, the risk of repetitive strain injuries is significantly reduced9.

Integrating Automation

Automation has numerous advantages over manual NGS liquid dispensing; however, automation comes in different levels and the associated benefits vary between systems. In NGS, the choice between fully automated and semi-automated workflows presents a trade-off between efficiency, flexibility, and investment10.

Fully Automated vs. Semi-Automated Workflows

Fully automated systems enable high-volume sequencing by significantly reducing human error and enhancing throughput and data quality, albeit with higher initial investments, lower flexibility, and integration complexities. Semi-automated workflows are less costly, simpler to set up and maintain, and more customizable. However, semi-automated workflows have more manual steps and are, therefore, more prone to human error. Ultimately, the choice depends on the specific project requirements, with each system offering distinct advantages tailored to different operational scales and objectives.

For laboratories with little to no experience with automated systems, selecting a walkup-friendly solution for NGS liquid dispensing has a far lower entry barrier, owing to less training required, lower costs and easier integration into existing workflows. Certain semi-automated systems can also be integrated with other systems, enhancing the level of automation in line with the laboratory's needs. For example, DISPENDIX’s I.DOT Liquid Handler is integrated within the G.STATION NGS Workstation to fully automate the entire library preparation process (Fig. 2).

Figure 2. The G.STATION is an automated NGS workstation comprising the best tools for each NGS library preparation workflow step.

Key Considerations for Integration

When integrating new automation technologies into existing NGS workflows, several key considerations ensure a seamless transition and optimal operational efficiency.

- Compatibility with existing equipment and labware – Users should ensure new systems align with current equipment regarding hardware and software compatibility, avoiding disruptions and maximizing cost savings.

- Workflow optimization and protocol adaptation – While selecting an automated solution that fits seamlessly into existing workflows is beneficial, sometimes workflows need to be adapted to maximize the benefits of the new technology. This can include reducing manual steps and adjusting data management practices to handle new data types or volumes to maximize the system’s potential.

- Training and support for lab personnel – Selecting a user-friendly system can accelerate its integration, particularly in laboratories with many staff or a high staff turnover. However, comprehensive training and ongoing support are necessary to ensure optimal performance.

Conclusion

The integration of NGS liquid dispensing automation into library preparation workflows significantly enhances efficiency, accuracy, safety, and cost-effectiveness, addressing the limitations posed by manual library preparation. This can improve the quality and integrity of sequencing data, which is critical for fundamental research, diagnostics, and personalized medicine.

Fully automated and semi-automated solutions cater to distinct efficiency, flexibility, and investment requirements. Partnering with expert vendors like DISPENDIX is crucial for navigating the integration process, optimizing workflows, and ensuring compatibility with existing systems.

Struggling with tedious NGS library prep? DISPENDIX’s I.DOT and G.PURE bundle automate 80% of the process, boosting accuracy and efficiency and saving costs. Book a demo today and learn how these user-friendly tools can revolutionize your research!

References

- Vandeputte M. The journey from next-generation sequencing to personalized medicine? The Biochemist. 2021;43(6):4-8. doi:10.1042/bio_2021_192

- Milestones in Genomic Sequencing. Accessed March 13, 2024. https://www.nature.com/articles/d42859-020-00099-0

- Fernandez-Marmiesse A, Gouveia S, Couce ML. NGS Technologies as a Turning Point in Rare Disease Research , Diagnosis and Treatment. Curr Med Chem. 2018;25(3):404-432. doi:10.2174/0929867324666170718101946

- Brittain HK, Scott R, Thomas E. The rise of the genome and personalised medicine. Clin Med Lond Engl. 2017;17(6):545-551. doi:10.7861/clinmedicine.17-6-545

- Socea JN, Stone VN, Qian X, Gibbs PL, Levinson KJ. Implementing laboratory automation for next-generation sequencing: benefits and challenges for library preparation. Front Public Health. 2023;11:1195581. doi:10.3389/fpubh.2023.1195581

- Tripathi P, Singh J, Lal JA, Tripathi V. Next-Generation Sequencing: An Emerging Tool for Drug Designing. Curr Pharm Des. 2019;25(31):3350-3357. doi:10.2174/1381612825666190911155508

- Muscarella, Fabrizio, De Bonis, et al. Automated Workflow for Somatic and Germline Next Generation Sequencing Analysis in Routine Clinical Cancer Diagnostics. Cancers. 2019;11(11):1691. doi:10.3390/cancers11111691

- Dahui Q. Next-generation sequencing and its clinical application. Cancer Biol Med. 2019;16(1):4-10. doi:10.20892/j.issn.2095-3941.2018.0055

- Holland I, Davies JA. Automation in the Life Science Research Laboratory. Front Bioeng Biotechnol. 2020;8:571777. doi:10.3389/fbioe.2020.571777

- Christler A, Felföldi E, Mosor M, et al. Semi-automation of process analytics reduces operator effect. Bioprocess Biosyst Eng. 2020;43(5):753-764. doi:10.1007/s00449-019-02254-y